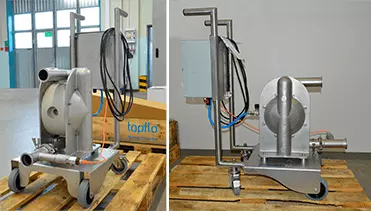

The client, pharmaceutical industry company, requested mobile pump with height adjustable inlet so it can be adjusted to match different tank outlet heights for emptying waste ointments and creams from mobile tanks.

Tapflo's Engineering to Order team met these requirements with TX220 metal diaphragm pump assembled on a hygienic trolley equipped with screws regulating the level of baseplate with the pump. The height adjustment range is 240-450 millimeters. The process of adjustment is easy and take very little time (about 1-2 minutes).

Comparing to our competition, the main advantage of the unit is the use of trapezoidal screws (widely used in workshop tables, car lifts, CNC machines for lifting and positioning). This solution ensures easy height regulation and is more reliable, stable and safe in comparison to ordinary M thread, which may easily break, seize or cold-weld. Additionally, the screws have casings to ensure safety usage.

Should you need similar solution or tailored to your specific needs please contact us at sales@tapflo.com or contact your local Tapflo dealer: http://tapflo.com/en/contact

Related materials |

|

Product page: |

|

Brochure: Mobile solution for pump units and systems

|

Next Case study

Diaphragm pump for pharmaceutical industry

T220 metal diaphragm pump mounted on an industrial trolley, designed for the final customer from pharmaceutical industry.