| Model | Max capacity [lt/h] | Max pressure [barg] |

| B & BR 125N | 108 | 20/13,5 |

| B & BR 175N | 418 | 20/14 |

| B & BR 250N | 1068 | 11/7,2 |

| APB & BR 125N | 60 | 60/40 |

| APB & BR 175N | 247 | 60/40 |

| APB & BR 250N | 556 | 23/20,7 |

Material execution

| Execution | Pump head | Piston | Valve (ball) | Valve seats | Diaphragm | Valves O-ring |

| 29 | PP | S.S. 420 TEMP. | PYREX | PP | PTFE/NBR | T20 |

| 41 | S.S. 316 | S.S. 420 TEMP. | S.S. 316 | S.S. 316 | PTFE/NBR | T20 |

| 43 | PVC | S.S. 420 TEMP. | PYREX | PVC | PTFE/NBR | T20 |

PP = polypropylene, AISI 420 TEMP. = tempered stainless, T20 = polyurethane rubber, PYREX~glass

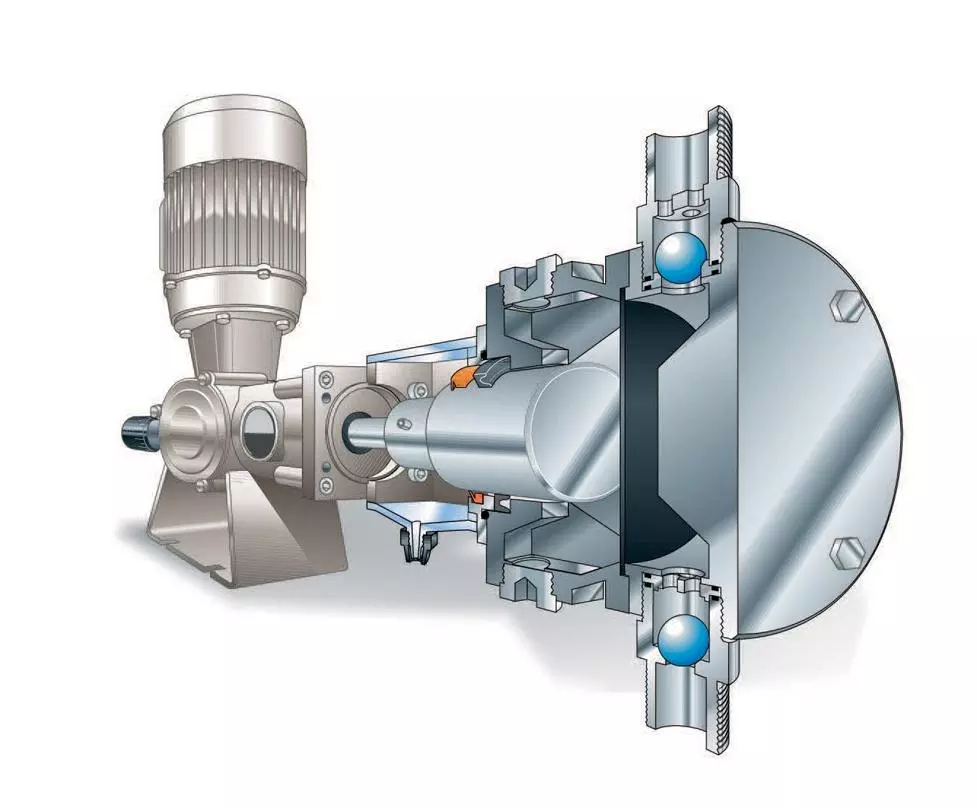

Spring return hydraulic diaphragm dosing pump

„B & BR” - Series Hydraulic diaphragm metering pumps are normally used when:

- The dosed liquid contains small amounts of suspended solids

- A drip proof/air tight application is required

- The dosed liquid is a toxic solution

- High pressure is required

Each pump is fitted with a standard gearbox reduction system with a vertical mounted motor. The reduction gearbox is of a standard endless screw plus worm-wheel type, supported by bearing, fully lubricated in oil bath.

Stroke adjustment can be carried with the pump at rest or in operation and it can be manual or automatic through automatic actuator driven by 4-20 mA; different BUS; pneumatic. BR version is equipped with built-in safety valve is installed in the hydraulic circuit, in order to protect the diaphragm against over pressure.

Furthermore they comply with ATEX standard, therefore they can be installed in Hazardous area.

Fittings:

- Polyethylene tanks

- Relief valves and back pressure valves

- Safety relief valve

- Injection valve

- Foot valve

- Pulsation dampeners

- Calibration pot