Materials, data and limits

| Technical data | Specification |

| Casing material | Aluminium |

| Hose material (wetted) |

Industrial reinforced - NR (std), NBR, EPDM, CSM ATEX reinforced - NR, EPDM Food grade reinforced - NR FDA, NBR FDA, EPDM FDA Extruded hose - Silicone |

| Insert material (wetted) |

AISI 316L (std), PTFE, PE AST, PP |

| Connection type | Hose tail (std), EN1092-1 Flange, ANSI flange, BSP/NPT thread, Camlock, DIN 32676 clamp, DIN 11851 thread, SMS 3017 clamp |

| Motor* | IEC standard, 3-phase, 4-pole, 50/60 Hz, IP55+PTC |

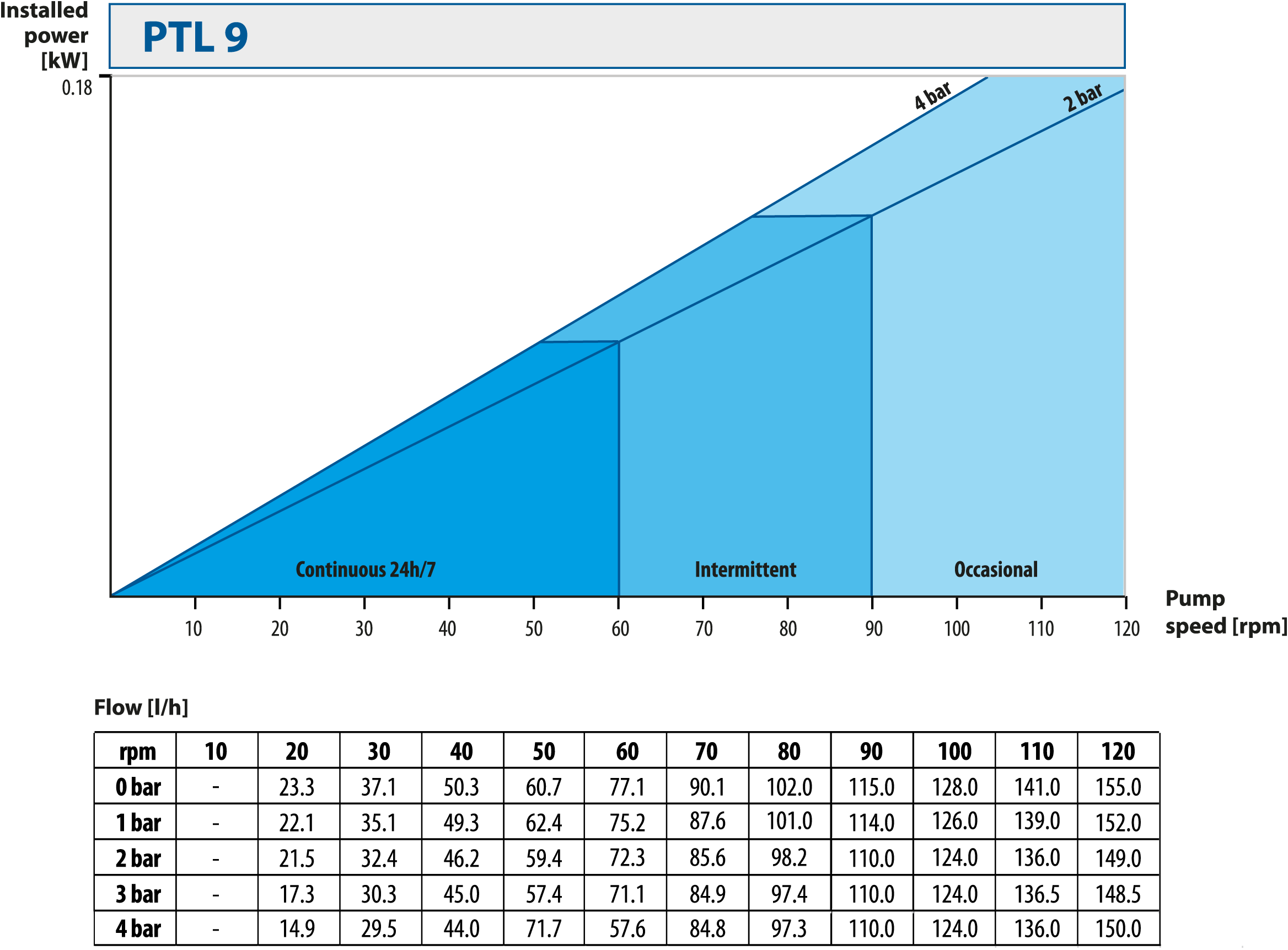

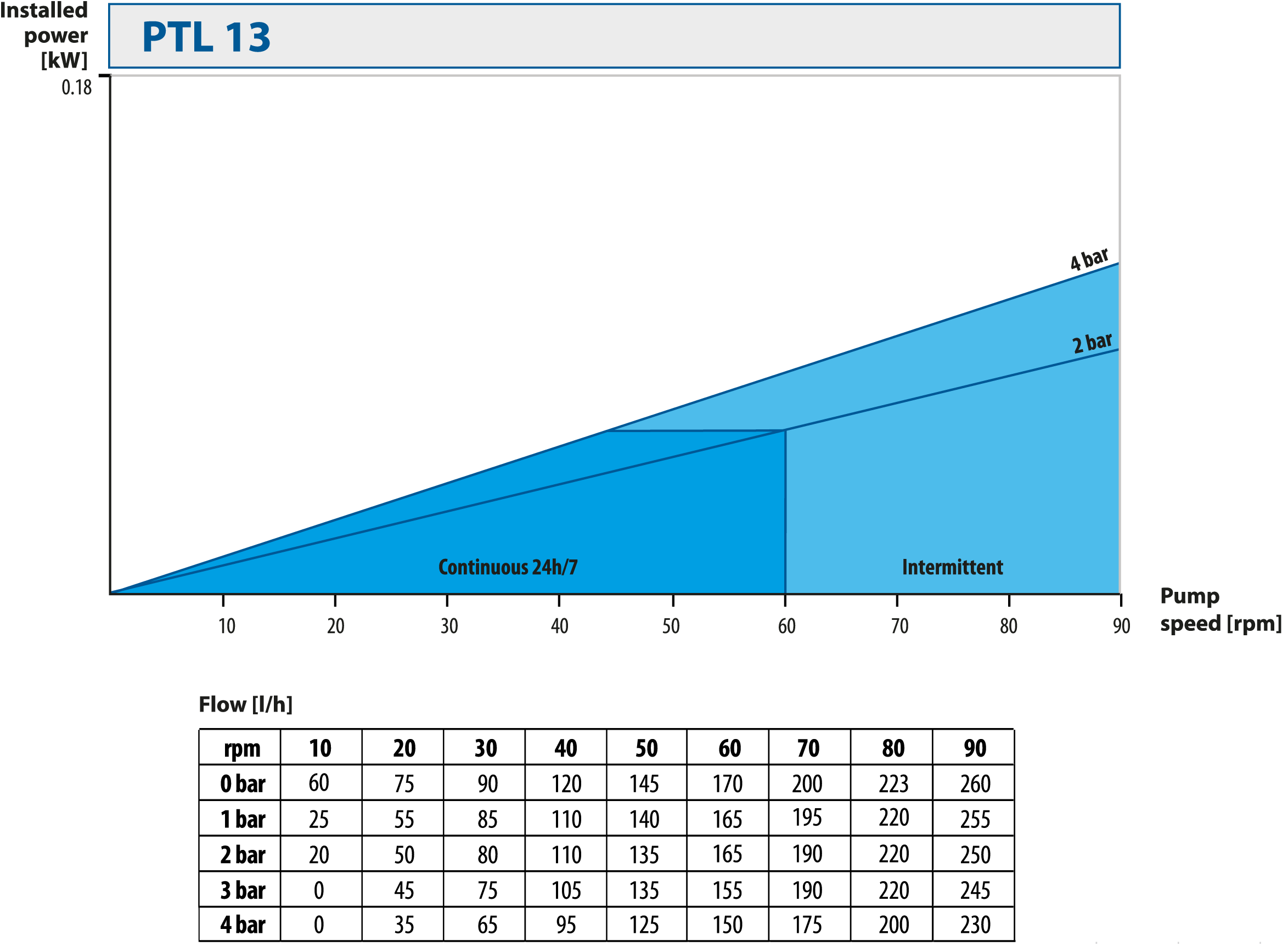

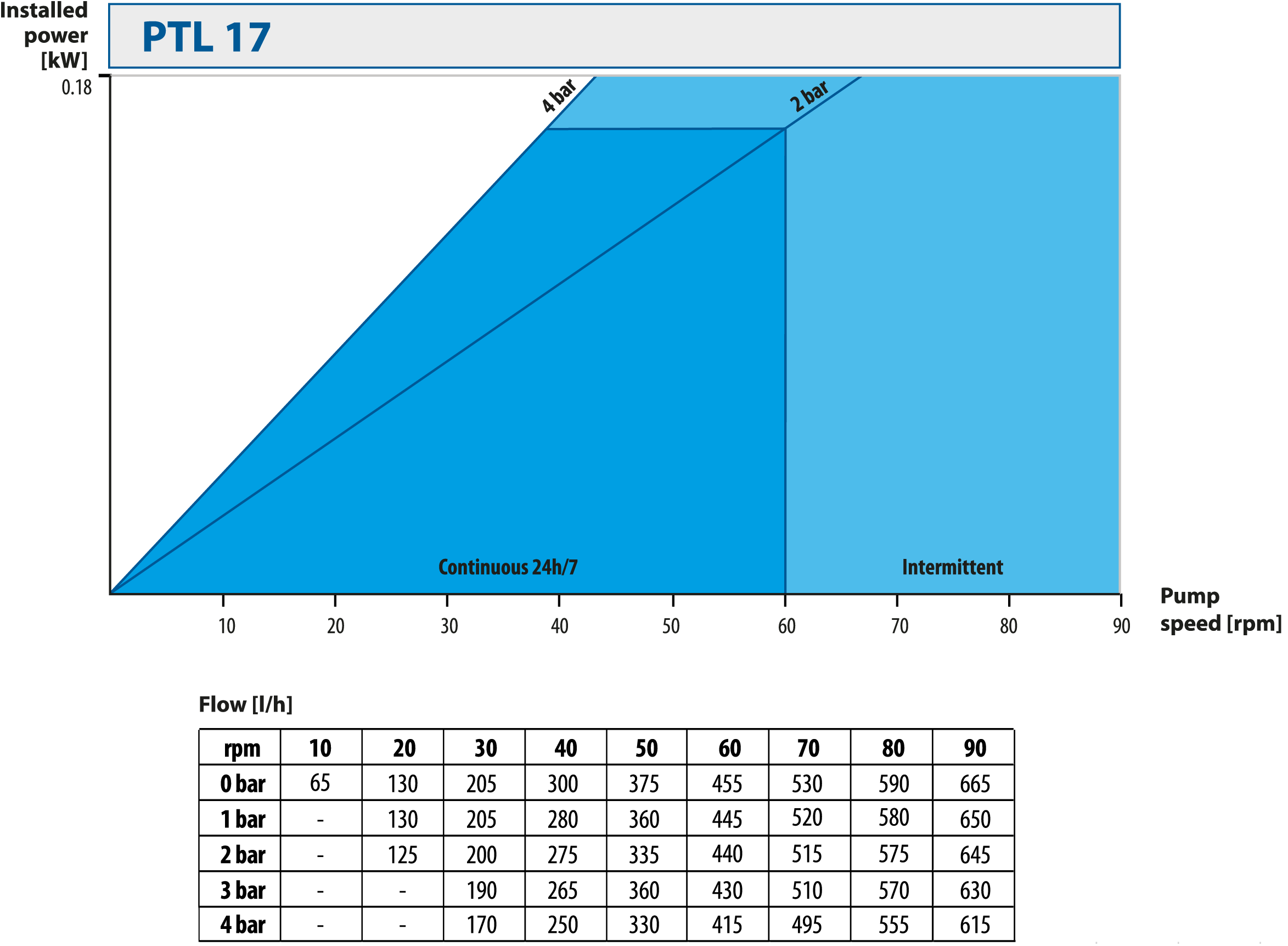

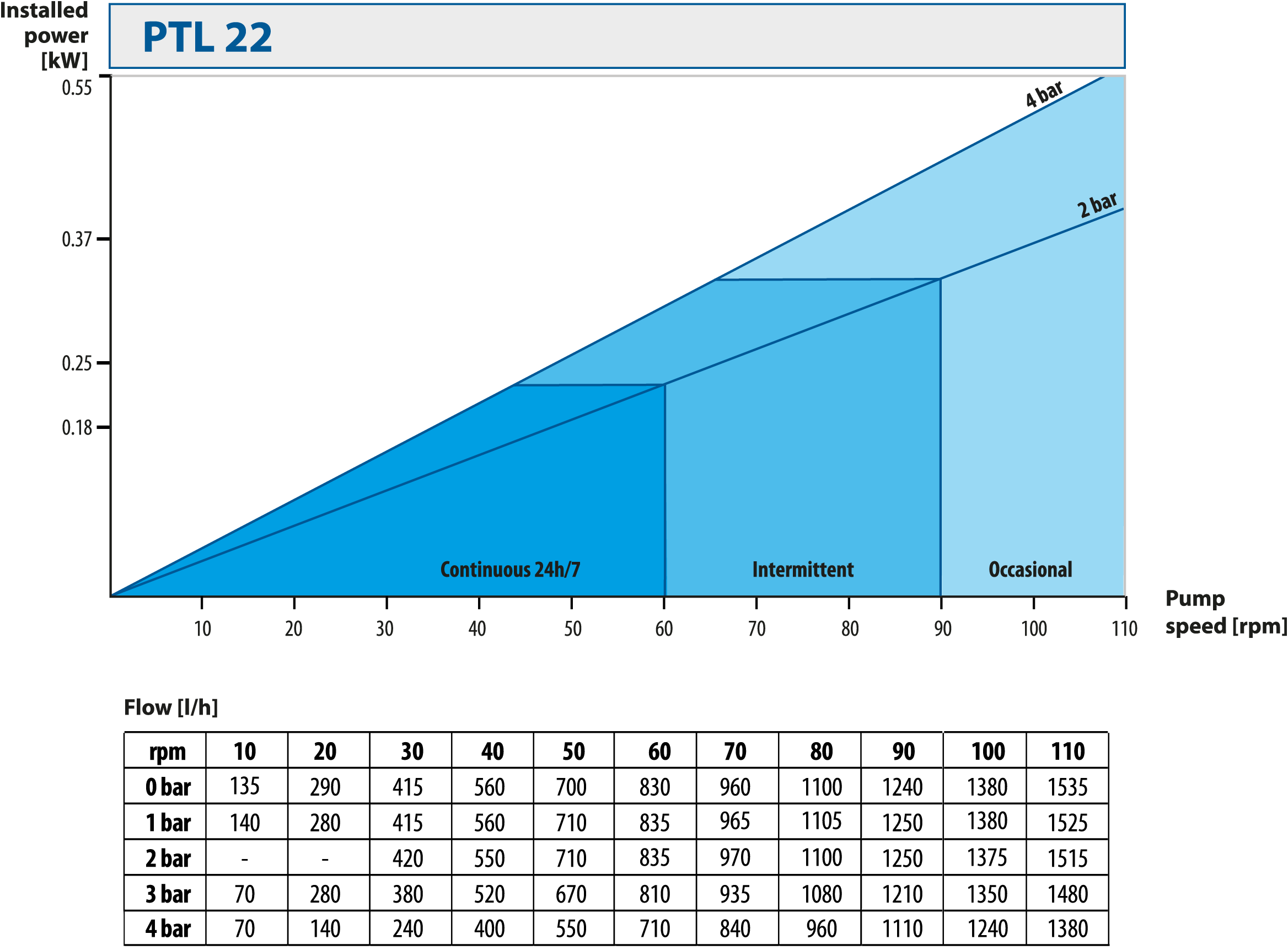

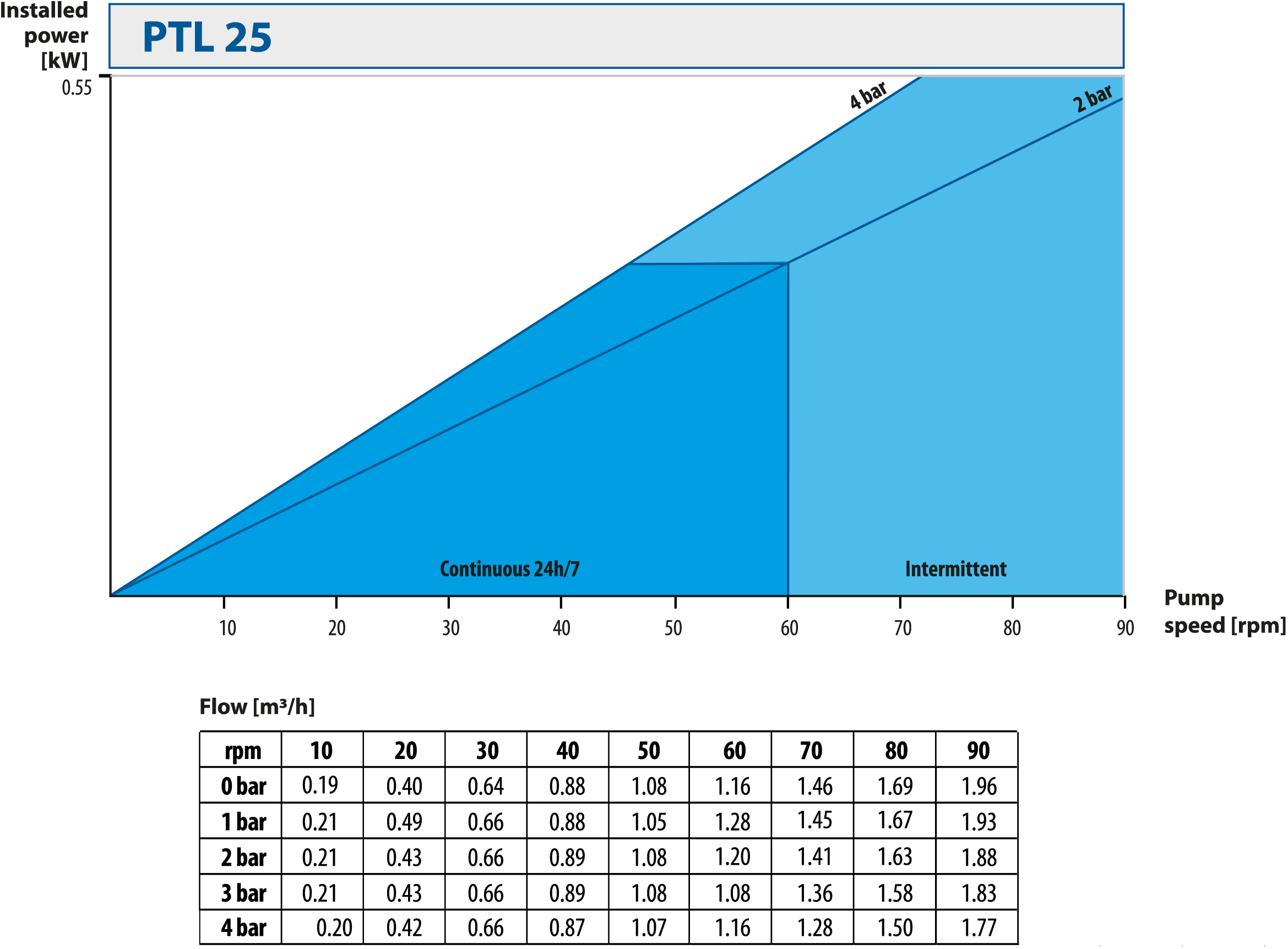

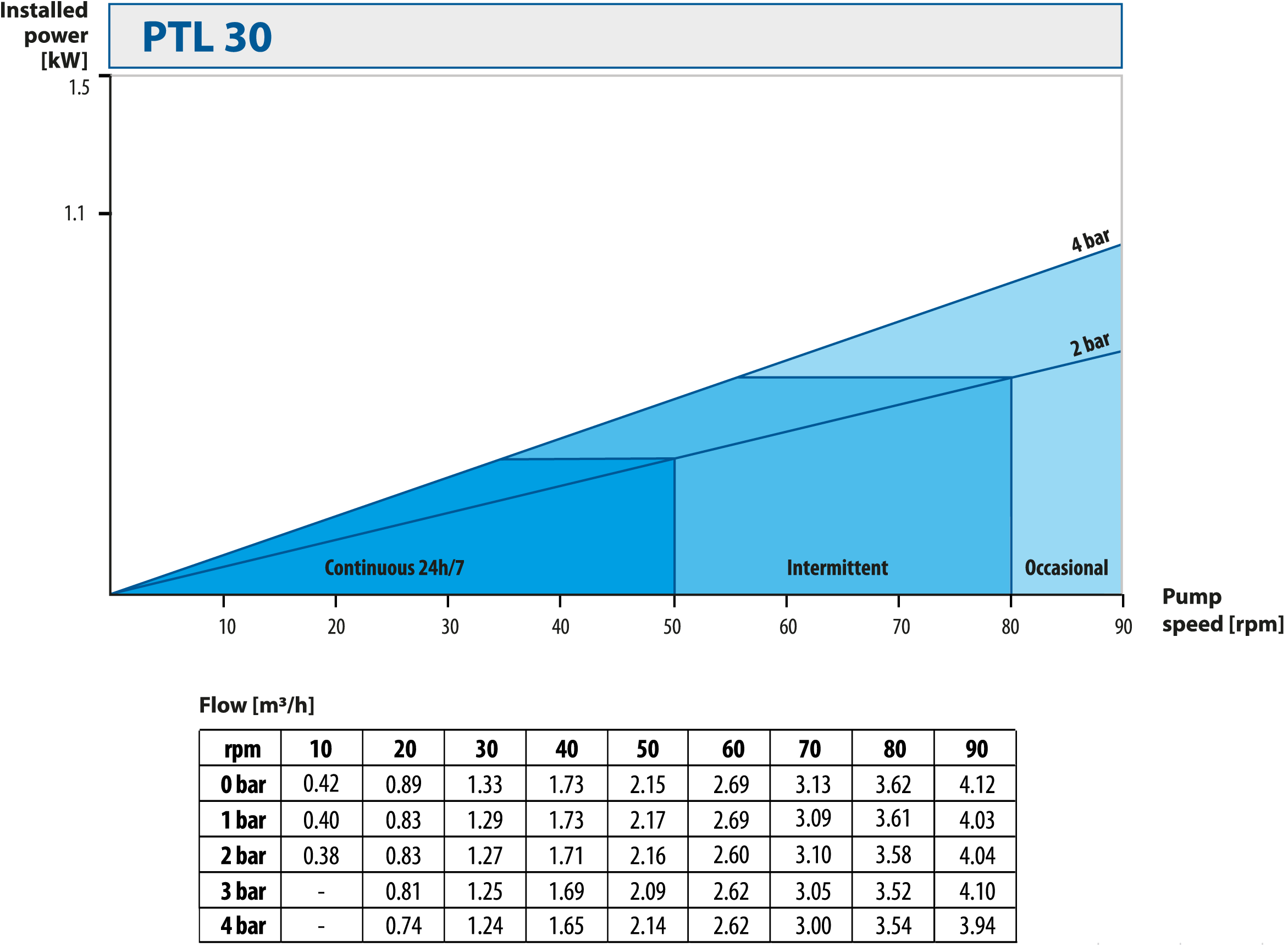

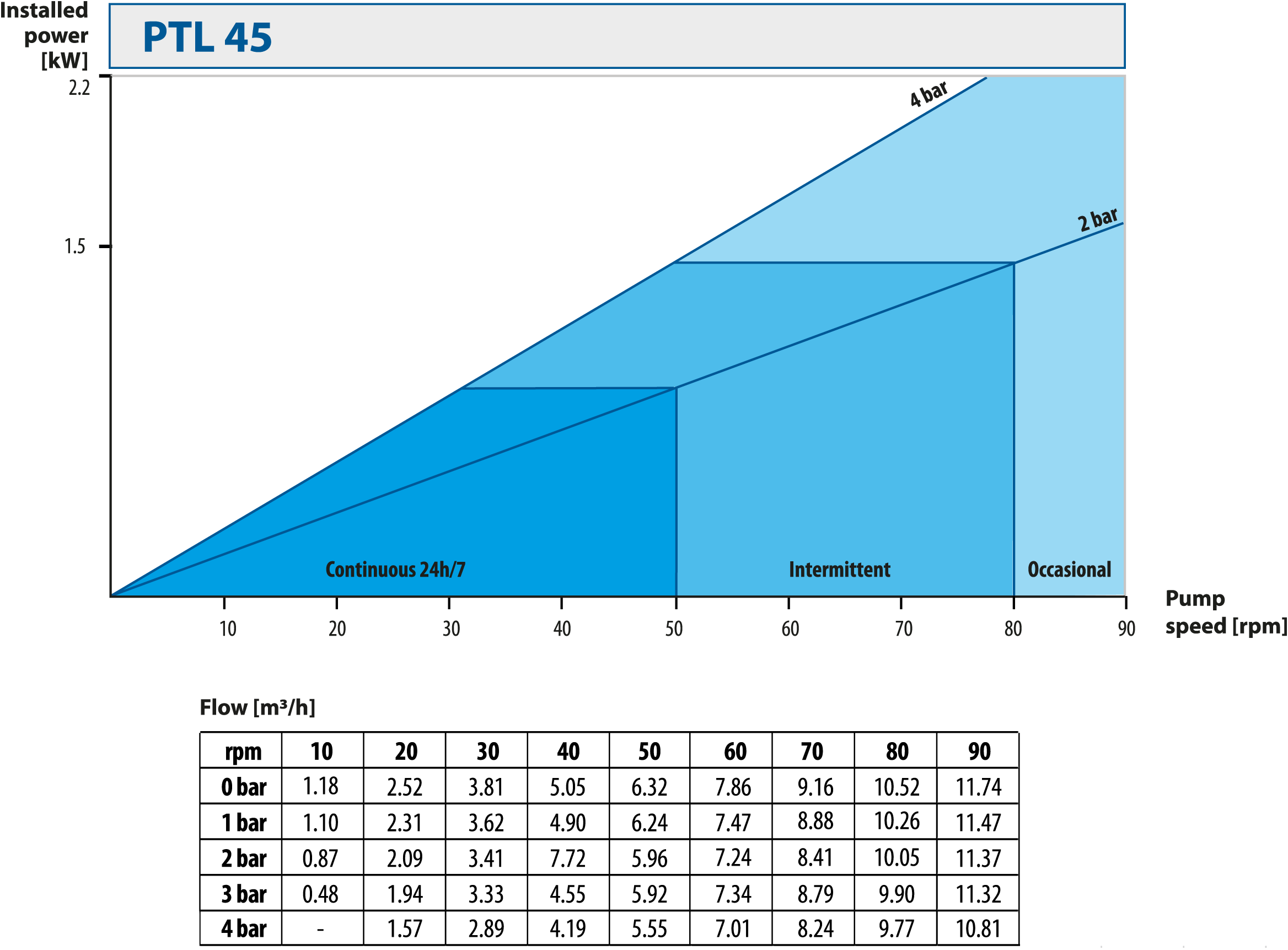

| Max. capacity | 5 m3/h |

| Max. viscosity | 12 000 cP*** |

| Max. liquid temp. | 80 ºC** |

| Max. discharge pressure | 4 bar (with reinforced hose) |

| Max. suction lift | - 0.9 bar |

| * Other motor options available on request ** At a room temperature of 20°C. Furthermore, it depends on the pumped fluid and on the hose material *** Maximum value may vary depending on pump size and installation |

|

Applications

pharmaceutical, water treatment food & beverage, cosmetics, chemical

- Capacity up to 5 m3/h

- roller design

- lubricant type: silicone grease (food approved)

- housing material: aluminium

- 7 sizes available

- horizontal and vertical gear motor position

FEATURES & BENEFITS

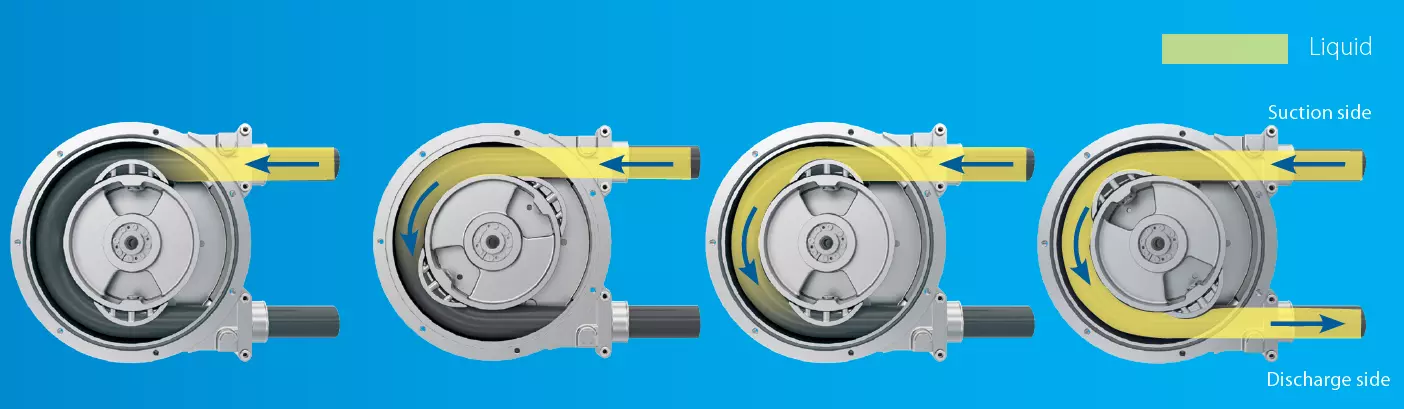

- Pumping challenging liquids

Hose pumps are suitable for efficiently pumping highly abrasive, corrosive, and viscous liquids containing particles. - Ease maintenance, reduced downtime

Hassle-free maintenance and minimal downtime due to few components and no seals required. - Easy operation

User-friendly operation without the need for specialized personnel. - Cost-effective solution

Total Cost of Ownership (TCO) for economical pumping solutions. - Turbulence-free performance

Smooth and gentle pumping even with highly abrasive or sensitive liquids, minimizing wear and ensuring optimal operations. - Extensive configuration options

The pump connection offers a diverse range of types and orientations. - Self-priming

Efficient self-priming with superior suction capacity up to -0.9 bar. - Handling high viscosity

Reliable performance with the ability to pump liquids with viscosities up to 100,000cP. - Reversible operation

Versatile functionality for various applications with an easy change of rotation direction. - Adjustable flow and precise dosing

Flexibility in flow rates and precise dosing accuracy of approximately ±5% by adjusting the speed, such as with a frequency converter. - Safe to run dry

Safe to run dry, eliminating the need for monitoring and ensuring ease of use and peace of mind.