ENQUIRE NOW

World of tapflo

World of tapflo

- EUROPE

- Albania

- Austria

- Baltic States

- Belarus

- Belgium

- Bosnia & Herzegovina

- Bulgaria

- Croatia

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Ireland

- Italy

- Latvia

- Lithuania

- Macedonia

- Montenegro

- Norway

- Poland

- Portugal

- Romania

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- The Netherlands

- Ukraine

- United Kingdom

- ASIA & PACIFIC

- Australia

- Cambodia

- China

- India

- Indonesia

- Japan

- Kazakhstan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Taiwan

- Thailand

- Turkey

- Uzbekistan

- Vietnam

- HOME

- ABOUT US

- PRODUCTS

- PRODUCTS

- See all

- Air operated diaphragm pumps

- Air operated diaphragm pumps

- See all

- PE & PTFE pumps

- PE & PTFE pumps

- See all

- PE & PTFE versions

- Sanitary pumps

- Sanitary pumps

- See all

- Sanitary versions

- Metal Pumps

- Metal Pumps

- See all

- Metal versions

- Pharmaceutical pumps

- Aseptic pumps EHEDG certified

- Powder pumps

- TC Intelligent pumps

- Electrically operated diaphragm pumps

- Pulsation dampeners

- Filter Press pumps

- Filter Press pumps

- See all

- AODD Filter Press pumps

- Steinle Filter Press pumps

- Centrifugal pumps

- Centrifugal pumps

- See all

- CTI industrial pumps

- CTH hygienic pumps

- CTM Magnetic drive pumps

- CTV Vertical Pumps

- CTS series self-priming

- CTS series self-priming

- See all

- CTS pumps execution versions

- CTP Plastic Pumps

- CTX High performance pumps

- CTX High performance pumps

- See all

- CTX H - hygienic series

- CTX I - industrial series

- CTXS - Self-priming pumps

- Hose pumps

- Dosing pumps

- Sinusoidal pumps

- Industrial mixers

- Filter units

- Accessories

- Tapflo Solutions ™

- Applications

- Applications

- See all

- Hygienic & Sanitary

- Industrial

- Brochures & Manuals

- TAPFLO SOLUTIONS

- CASE STUDIES

- CASE STUDIES

- DIAPHRAGM PUMP FOR UNLOADING IBC

- DIAPHRAGM PUMP WITH BUILT-ON PULSATION DAMPENER

- OIL AND FAT COLLECTION

- CTH FOR THE BREWERY INDUSTRY

- CTH FOR THE DISTILLERY INDUSTRY

- METAL DIAPHRAGM PUMP FOR CHEMICAL INDUSTRY

- EMERGENCY SITUATIONS PUMPS

- WASHING LINE SYSTEMS: CTV AND T50 PUMPS

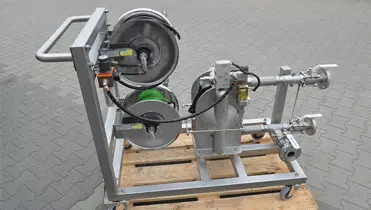

- MOBILE PUMP WITH HEIGHT ADJUSTABLE INLET

- DIAPHRAGM PUMP FOR THE NUCLEAR INDUSTRY

- TAPFLO PUMPS - LONG LIFE DESIGN AND ROBUSTNESS.

- TC INTELLIGENT PUMP FOR THE CERAMIC INDUSTRY

- WASTEWATER TREATMENT PLANT IN CZECHIA

- TR20 PTT INSTALLED ON THE CONTAINER

- PUMP FOR LIQUID SOAP

- DIAPHRAGM PUMPS FOR CASEIN GLUE PUMPING

- SANITARY PUMP IN NOISE REDUCTION BOX ON HYGIENIC TROLLEY

- HOW WE ADD VALUE WITH OUR FAST DELIVERIES

- ANOTHER SUCCESSFUL PROJECT FOR A LEADING MULTI-NATION PHARMACEUTICAL MANUFACTURER

- NEWS & MEDIA

- CONTACT

NEW: Tapflo Academy

NEW: Tapflo Academy